ROLL FORMED HUB ASSEMBLY

Proper preload of the bearing and race is not only critical to a hub assembly’s performance and service life, but also important to ensure the safety of a vehicle. To increase the durability and performance of a hub assembly, and to prevent artificial mistakes of improper torqueing, Roll Forming technology was innovated. Roll Forming technology provide precise bearing preload and improved overall strength to the Hub Assembly for secure clamping to the CV joint and knuckle for optimum vehicle safety.

However, not all roll formed hub assemblies are created equal! Roll forming design can cause potential issue on cracking during roll forming process if a manufacturer can’t well control their manufacturing processes.

WJB Automotive’s Roll Formed Hub Assemblies are manufactured under rigorously controlled manufacturing processes with high quality raw materials to ensure optimal strength and preload.

- Precise bearing preload and assembly tolerances

- Improves vehicle steering accuracy

- Higher dynamic and static loading

- Curling Thickness is thicker than average roll formed hub assemblies in the market

- Large slinger diameter of spindle, larger OD diameter of inner ring, smaller diameter of hub, which enhanced the stability of ball contact trail at big lateral force

HD HUB ASSEMBLY

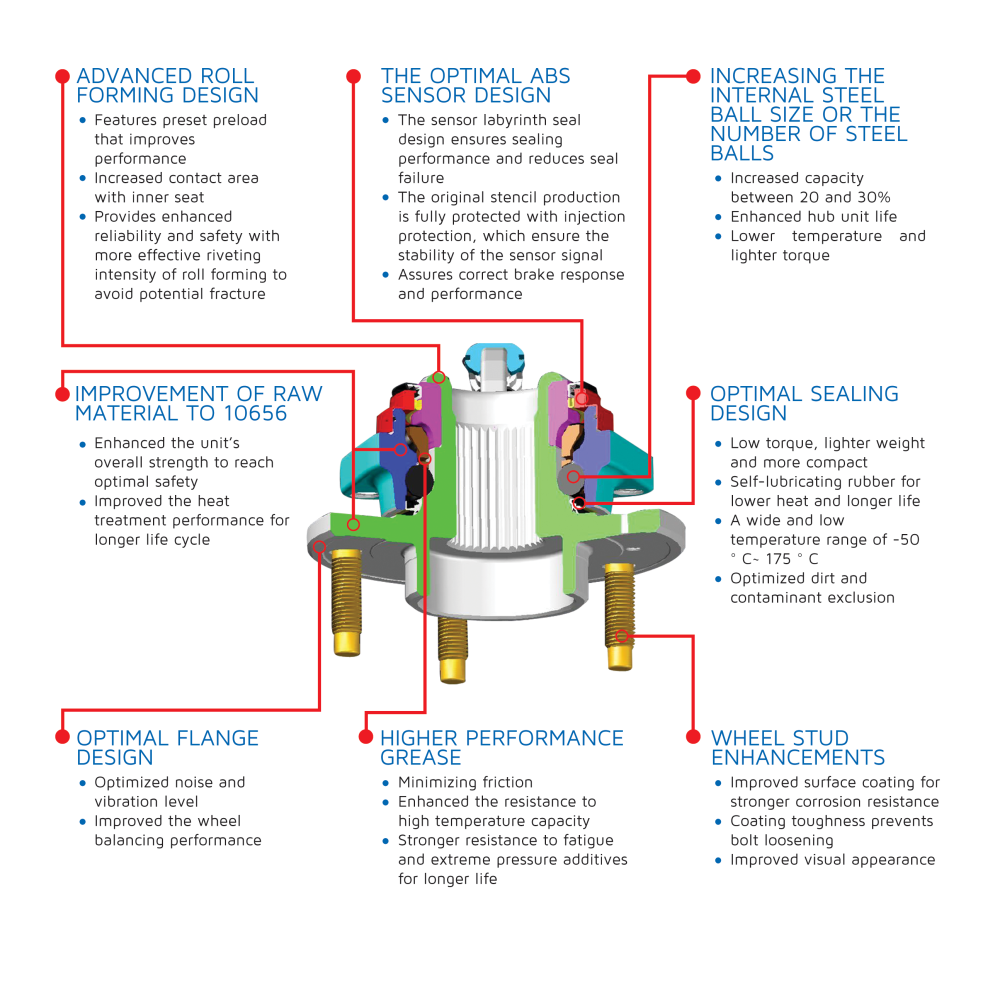

Roll forming technology is only part of the overall enhancements WJB Automotive made to its Hub Assembly line. The company has taken its Hub Assembly line to the next level with further overall design, durability and performance improvements with the introduction of WJB HD HUB ASSEMBLIES.

Write A Comment